Nowadays the cold chain and its management are assuming a role of fundamental importance both for the maintenance of product quality during the various processing phases up to the display on the sales counters and final consumption, and for a better energy efficiency of the deep-freezing process itself. Both in Europe and in Italy, in fact, frozen products are experiencing a continuous increase in consumption at an annual rate of 2.7% for a market value of over 100 billion euros. IIAS (Istituto Italiano Alimenti Surgelati) reports a national consumption of 849,900 tons in 2019 (+1.3% compared to 2018), corresponding to a per capita annual consumption of over 14 kg, for a total market value estimated at 4,400/4,700 million euros.

The CoACh project (Cold management in Agro-food Chains: solutions for process digitalization) fits into this context of growth and it involves some industrial partners (e.g. Orogel Società Cooperativa Agricola) and several university research centres, including CRAST of Università Cattolica del Sacro Cuore. The project, coordinated by Siteia.Parma, a research centre of the University of Parma, has several objectives, including the analysis of the freezing process, the ability to identify critical issues in relation to the relationship between production and cold chain, the development of models for the simulation of the refrigeration and freezing process and the development of optimization algorithms for cold management.

In this project, CRAST deals specifically with the development of a mathematical model of the freezing phase of vegetable processing. The final objective is to have a tool that allows to predict operational parameters and performance indices of the process. Based on mass and energy balances, this model will then be used, always within the project, in combination with optimization algorithms in order to manage the production of air used as cooling fluid in the most energy-efficient way.

In particular, the model will allow to verify the effects that variations in the air produced, for example in terms of relative humidity or temperature, might have on the product itself, always ensuring the maintenance of the freezing characteristics. As far as I illustrate, the model must require reduced resolution times, while maintaining a good accuracy in the evaluation of key parameters such as, for example, the variation of temperature over time in the thermally disadvantaged point of the food. A thorough analysis of the scientific literature has shown that there are three main categories of models of the freezing process: empirical models, theoretical models, mixed models. The latter were found to be suitable for this project as they have reduced resolution times and are found to be quite accurate.

In detail, they use empirical formulas for the evaluation of properties, while solving the heat diffusion equation in one dimension, thus allowing to evaluate the temperature trend inside the food. However, these models have some shortcomings, resolved in the course of the project, such as the inability to evaluate the variation of temperatures for finite objects, albeit simple, such as a parallelepiped or a cylinder to which it is possible to assimilate food (think, for example, of spinach cubes or French fries). Once the model type was selected and developed, another key aspect was the evaluation of the food properties (e.g. specific heat, conductivity, density, etc.). These properties strongly depend on the chemical composition of the food and its temperature. Therefore, it was decided to define the different types of food on the basis of their main constituents, namely water, protein, fat, carbohydrates, fibre and ash. This approach certainly has limitations, but it allows flexibility by ensuring rapid characterization of the food itself through the use of rapid and widely validated analytical methods. For example, thanks to this model, it could be possible to adapt freezing times according to the different batches of the same food to be frozen and not only according to the different types of food.

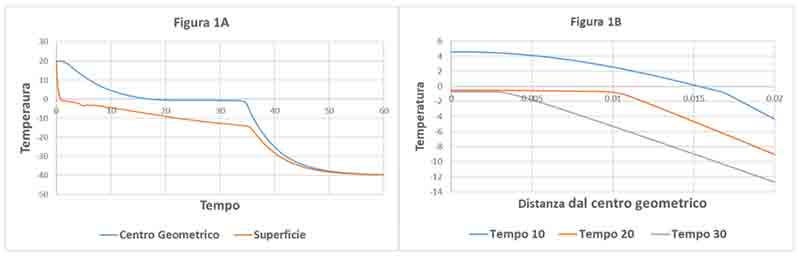

As an example, some of the possible results that can be obtained from the model used are shown, such as the variation of temperature as a function of time in the geometric centre of the food and on the surface (Figure 1-A) and as a function of distance from the geometric centre at a certain instant of time (Figure 1-B).

Figure 1: A-variation of temperature over time at the geometric centre and at the food surface, B-variation of temperature as a function of distance from the geometric centre at three different times.

In conclusion, the model developed within the CoACh project is efficient, flexible (being able to represent different types of food) and at the same time accurate, if the food considered can be assimilated to a defined geometric figure. This model will be used to energetically optimize the cold air process and production. Moreover, it can be used to try to reduce the freezing time of the food.

It is interesting to underline how the freezing process can be included in an energy optimization program that also includes the subsequent phases, such as transport and storage. From this point of view, the frozen product can also be used as an energy accumulator to be exploited in the subsequent phases, always guaranteeing the quality of the food. Although there are several studies on this subject, this type of approach can still be improved from the point of view of both empirical properties and the geometric shapes allowed to define a food.